When it comes to industrial and commercial heating, the choice between direct and indirect gas-fired heating systems is crucial. Each system has unique benefits and trade-offs, making it important to understand the applications, efficiencies, and costs associated with each.

What’s the Difference?

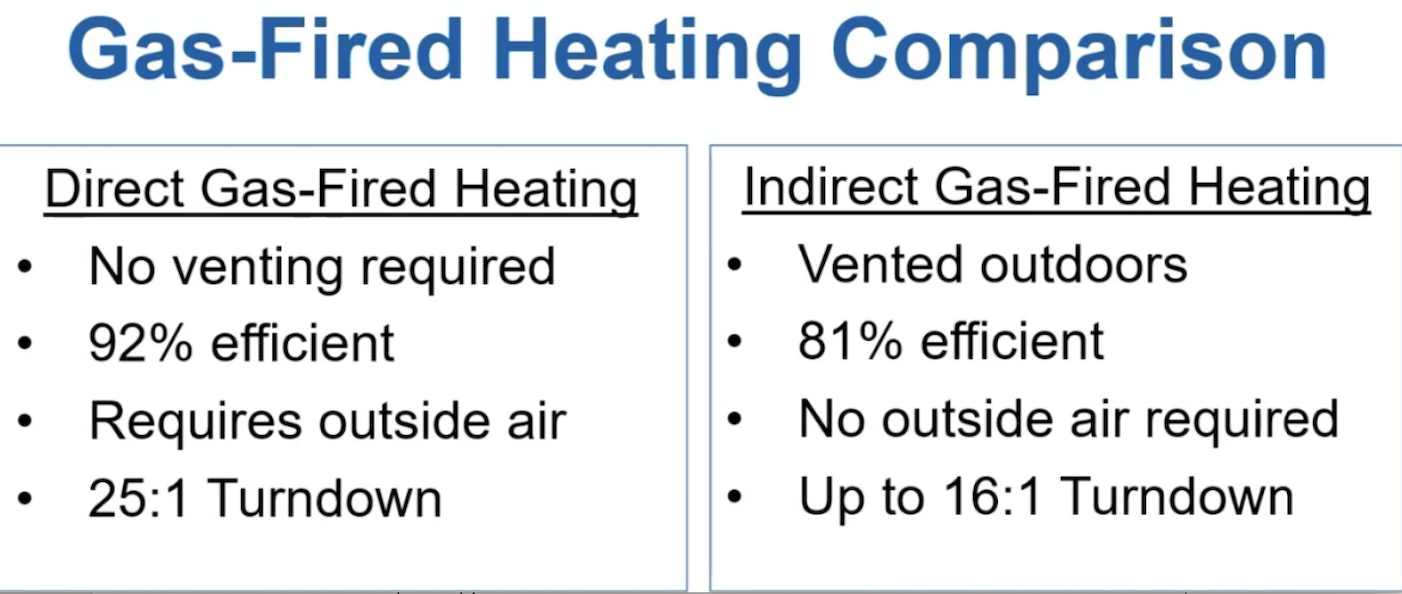

Direct gas-fired heating is often the go-to choice for makeup air applications due to its high efficiency and simplicity. With a direct system, 100% of the heat generated is transferred to the air passing over the burner, delivering an impressive 100% thermal efficiency. These systems rely on outside air, which eliminates the need for venting, making installation straightforward and cost-effective. Given these factors, direct gas-fired heating systems are an attractive option where gas is more affordable than electricity.

On the other hand, indirect gas-fired heating systems provide a different approach. These systems require outdoor venting to prevent combustion byproducts from entering occupied spaces. With indirect systems, heat is transferred from the combustion process through a heat exchanger before it reaches the air. While indirect systems offer more precise temperature control and the ability to recirculate air, they are less efficient (typically around 81%) and require more complex installation due to venting requirements if installed indoors.

Efficiency and Venting Considerations

Direct gas-fired systems boast 92% operational efficiency, compared to 81% for indirect systems. The key difference here lies in how heat is delivered to the space. Direct systems directly transfer heat from the burner into the air, meaning that every available BTU is used. This is particularly advantageous when gas prices are higher, as it maximizes energy usage and minimizes waste.

Indirect systems, while offering some advantages like air recirculation, require outdoor venting and careful handling of condensation, which can damage the system over time. With this in mind, Greenheck only offers non-condensing indirect furnaces.

Which System is Right for You?

Ultimately, the choice between direct and indirect gas-fired heating systems depends on the specific needs of your application. Direct systems offer unbeatable efficiency and simplicity, making them ideal for makeup air situations where gas prices are higher. Indirect systems offer the ability to prevent the products of combustion from entering the space which allows the ability to recirculated air over the heat exchanger if desired.

As with any major equipment decision, it’s important to weigh upfront costs against long-term operating expenses and maintenance needs. Direct gas-fired heating systems might be more cost-effective in many scenarios, but for applications that demand precise control and flexibility, the investment in an indirect system could be worthwhile.

If you’re unsure which system is best for your facility, call your Dorse rep and we can help you make an informed decision based on your unique needs.

Check out a short video about

gas-fired heating here.

You can also see other videos about a variety of HVAC solutions on our Youtube channel.